B&S Light Industries

Ez-Blend All-In-One Plant Control

© 2024 B&S Light Industries | 24905 S Hwy 66 | Claremore, OK | 74019 | Tel: 918-342-1160

Specializing in the Manufacture of Asphalt Plant Control Systems

Made with Xara

Ez-Blend | Ez-Blend Start/Stop | Ez-Loader II | eTicket | Ez-Batcher | Ez-Ticket II | Ez-Filler | Digi-Flow | BSI-1 | BSWB

Full Plant Control

Gone are the days of searching through a “rats nest” of wiring. Fully interlocked within the computer allows for minimal wiring. Most items require only single wire start and single wire confirm feedback hookup. Ez-Blend™ system can control 2 liquid asphalts, 6 recycled materials, 12 cold feed bins, multiple mineral fillers, baghouse fines, anti-strip, lime, rejuvenator and other materials. The system is specifically designed to be expandable to meet needs as the plant grows.

Premium Support

(918) 342-1160

Experience the unparalleled support enjoyed by our customers since 1983. support@bslight.com

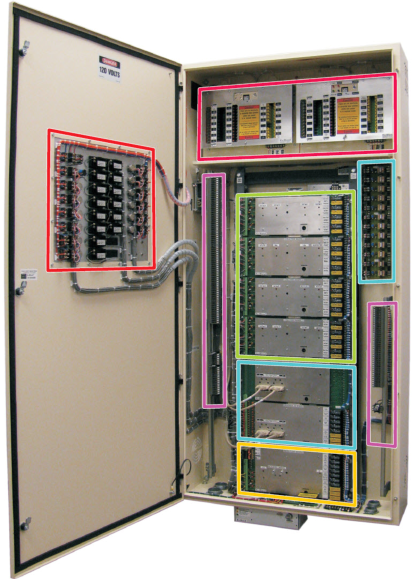

Cabinet Specs:

72” H x 36” W x 10” D

Shipped with 6” support legs

and mounting locations

to secure to a wall location.

• 48+ outputs, each with input feedback

confirmation, provides automatic start/stop and

adjustment of all systems in your plant including

conveyor belts, augers, drags, air-locks,screens and

pugmills, etc.,as needed by the mix formula,for true

“on the fly” mix changes.

• Fully interlocked start/stop functions customized to

your plant.

• Numerous Product Silo control methods. Multiple

flop gates and/or traverse belts capability provides

fully automated and interlocked control. Programmed

Silo Scripts ensure each style function seamlessly.

• 12 Amp Meter inputs, each with individual

Deviation Alarms, allow clear on-screen monitoring of

real-time rates.

• 16 Delivery System channels for Cold Feeds,

Recycle Materials,Silo Additives, Liquid Additives,Warm

Mix Additives, etc.

• Easy access terminals for field wiring. Prints are

custom each installation.

• Main Plant Interface provides AC Controls,

Internal/External Scales, Temperatures,Pressure

Readings, etc.

• A “true” Manual Panel provides hardware backup

control for each individual delivery system.